Consumer Electronics Mold Manufacturers

Product Overview

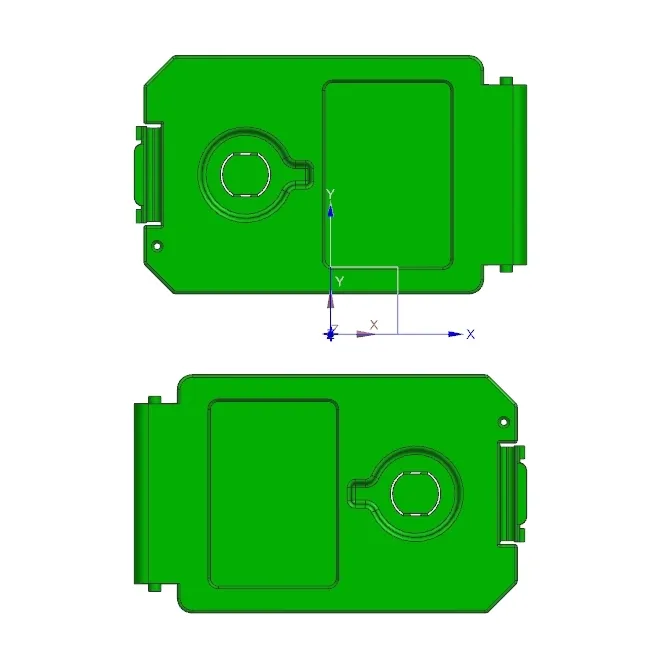

- The consumer electronics mold from GV Mold has undergone a well-designed process and strict testing by third parties, with continuous updates and readiness for user testing.

- It can be applied to different industries, fields, and scenes, providing opportunities for international applications.

Product Features

- The consumer electronics mold from GV Mold boasts better quality than other products in the industry, with a focus on design, manufacture, and applications.

- Precision and efficiency are key components in the design and manufacture of plastic instrument housing injection molds, ensuring high-quality results.

- The mold designs support the production of complex, reliable plastic components for industries like medical devices, electronics, and automotive.

- Highly intricate designs or standard components are catered to, offering cost-effective solutions to enhance functionality and reliability.

Product Value

- The consumer electronics mold from GV Mold offers high-quality, durable, and reliable plastic housings for various applications, with a focus on precision, efficiency, and long-term durability.

- The molds meet exact specifications, with a commitment to tailored solutions that meet technical requirements and budget constraints.

Product Advantages

- By streamlining the mold manufacturing process and focusing on cost-effectiveness, lead times are reduced while ensuring excellent product outcomes.

- The molds are designed with strategically positioned injection points for optimal material flow and enhanced part quality, with sophisticated cooling systems to maintain uniform cooling rates and reduce cycle times.

Application Scenarios

- The plastic instrument housing injection molds from GV Mold find applications in medical devices, electronics, automotive, and consumer products industries, ensuring precision, reliability, and strength.

- These molds create housings that safeguard internal components while allowing for easy assembly and maintenance, supporting the production of durable housings for instruments and controls in various fields.